Product Description

Renishaw M3 5-way 2 mm Ruby Ball Star Stylus (50 mm span)

This multi-tip star stylus can be used where contact with different surfaces is needed without changing the stylus. Ruby is regarded as the industry standard for stylus tips. It is one of the hardest materials available and suitable for most applications. Due to adhesive pickup, ruby tips are not recommended for scanning aluminium parts.

Star Styli

These stylus clusters provide you with multiple-tip probing of complex features and bores. Four or five ruby ball systems are mounted rigidly on a stainless steel center. Three standard sizes are offered – alternatively, you can create custom-made star styli using a 5-way stylus center and any of the genuine Renishaw stylus range.

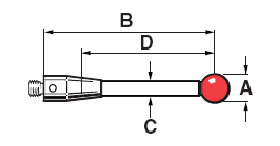

Star styli can be used to inspect a variety of different features. Their use can reduce inspection cycle times by allowing multi-tip probing, minimizing the need to move the probe to extreme points of internal features such as the sides or grooves in a bore. Using star styli also allows effective probing in the –Z (upwards) direction when using a 5-way probe, provided that the stylus tips extend beyond the diameter of the probe body. Each tip on a star stylus requires datuming (sometimes referred to as ‘qualifying’ or ‘calibrating’) in the same manner as a single-ball stylus. The 'span' of star styli is taken from ball center to ball center.

Ruby Ball Material

The industry standard and the optimum stylus ball material for a vast majority of measurement applications, ruby is one of the hardest known materials. Synthetic ruby is 99% pure aluminium oxide which is grown into crystals (or “boules”) at 2000 °C using the Verneuil process.

The boules are then cut and gradually machined into a highly spherical form. Ruby balls are exceptionally smooth on the surface, have great compressive strength and a high resistance to mechanical corrosion.

Very few applications exists where ruby is not the preferred ball material, however there are two applications where balls manufactured from other materials are recommended.

The first is for heavy duty scanning applications on aluminium. Because the materials attract, a phenomenon known as ‘adhesive wear’ can occur which involves build up of aluminium from the surface onto the ball. A better ball material for such applications is silicon nitride.

The second is in heavy duty scanning applications on cast iron. Interaction between the two materials can result in ‘abrasive wear’ of the ruby ball surface. For such applications, Zirconia balls are recommended.

Stainless Steel Stem Material

Stylus stems manufactured from stainless steel are used widely for styli with ball/tip diameters of 2 mm or greater and with lengths up to 30 mm. Within this range, one-piece steel stems offer the optimum stiffness to weight ratio, giving adequate ball/stem clearance without compromising stiffness with a joint between the stem and threaded body.

Please contact us if you require any styli with special ball materials. We can recommend the most suitable material for scanning different materials.

Part number: A-5003-0077