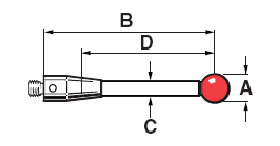

Product Description

Renishaw M3 0.5 mm Ruby Ball Stylus - Tungsten Carbide Stem (L 21 mm EWL 2mm)

Straight Styli

The simplest form of stylus, incorporating highly spherical industrial ruby balls and a choice of stem material.

Ruby is an extremely hard material and hence stylus wear is minimized. It is also of low density, keeping tip mass to a minimum, which avoids unwanted probe triggers caused by machine motion or vibration.

Mounted on stems made from a range of materials - stainless steel, tungsten carbide, ceramic, and a specialized carbon fiber material, "Renishaw GF" - these simple ruby ball styli are suitable for most inspection applications.

The size of the ball and the EWL of the stylus chosen are dictated by the size of the feature to be inspected. However, keeping the stylus ball as large as possible and the stem as short as possible will ensure maximum ball/stem clearance, whilst providing a greater yet still rigid EWL. Using larger ruby balls also reduces the effect of the surface finish of the component being inspected.

Ruby Ball Material

The industry standard and the optimum stylus ball material for a vast majority of measurement applications, ruby is one of the hardest known materials. Synthetic ruby is 99% pure aluminium oxide which is grown into crystals (or “boules”) at 2000 °C using the Verneuil process. The boules are then cut and gradually machined into a highly spherical form. Ruby balls are exceptionally smooth on the surface, have great compressive strength and a high resistance to mechanical corrosion. Very few applications exists where ruby is not the preferred ball material, however there are two applications where balls manufactured from other materials are recommended. The first is for heavy duty scanning applications on aluminium. Because the materials attract, a phenomenon known as ‘adhesive wear’ can occur which involves build up of aluminium from the surface onto the ball. A better ball material for such applications is silicon nitride. The second is in heavy duty scanning applications on cast iron. Interaction between the two materials can result in ‘abrasive wear’ of the ruby ball surface. For such applications, Zirconia balls are recommended.

Tungsten Carbide Stem Material

Tungsten carbide stems are best used for maximising stiffness with either small stem diameters required for ball diameters of 1 mm and below, or lengths up to 50 mm. Beyond this, weight can become a problem and stiffness is lost due to deflection at the stem to body joint.

Part number: A-5000-7632